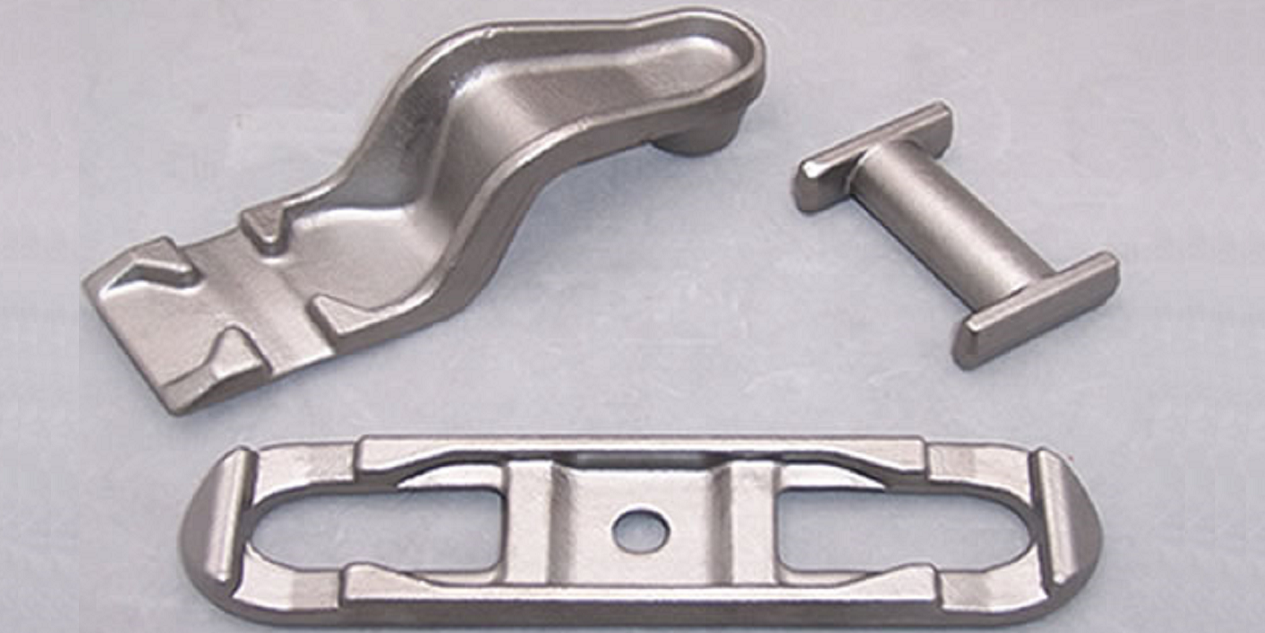

The automotive industry is continuously changing and one of the greatest new focuses in this industry is an emphasis on lightening materials used in the construction of vehicles. Pressings are produced by stamping and it is this method that is being used to replace some of the manufacturing methods from the past.

An age of lightweighting

“With today’s modern pressings, it’s possible to get the same strength out of lightweight materials”

While automobiles used to have very heavy components which were built to last for decades and designed to withstand even the toughest of impacts, many cars today are built with stronger and lighter materials that are designed to behave differently in an accident. Rather than focusing on safety and fuel economy, the automotive industry was more concerned with cars that would last forever and be strong. With today’s modern pressings however, it is possible to get the same strength out of lightweight materials.

Using pressings, as well as other lightweight materials in vehicles, also ensures that there can be a reduction in CO2 emissions. As cars work at burning less fuel to power them down the road and engines become more efficient, we can reduce carbon emissions worldwide. Forged steel components and some of the older manufacturing methods also had a detrimental effect on releasing CO2 into the atmosphere, so with pressings and stampings replacing forgings and castings, even greater CO2 emissions can be spared.

Perhaps the best aspect of these new manufacturing methods is that they are cheaper overall for the end consumer and for the manufacturer. The end consumer gets a car that is much more efficient on fuel, faster to produce and reasonably priced to buy. The manufacturer can cut down their lead times, costs to build and far more.

“Pressings and stampings will likely continue to become more widespread in vehicles in the future”

Pressings and stampings are now the new standard for automotive production and it is no wonder with all of these proven advantages. Pressings and stampings will likely continue to become more widespread in vehicles, especially as new alloys and materials become a part of vehicle design in the future.

—

Post from John Nollett